Hebei Chuanheng Auto Parts Co., Ltd.

Contact Us

Sales: +86-15200188018

Fax: +86-319-8138598

E-mail: hbgcjxc@126.com

Address: Wangguanzhuang Industrial Development Zone, Qinghe County

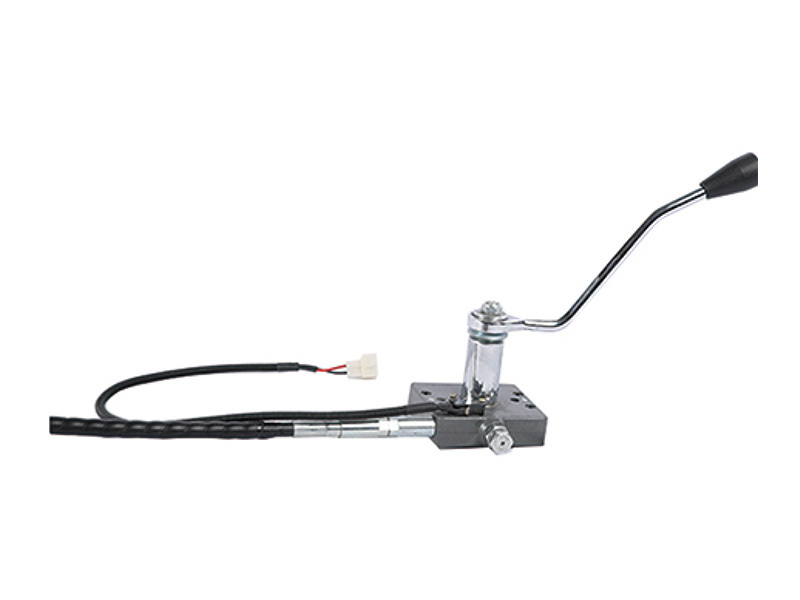

Variable Speed Assembly Series

Name:Double Transmission Assembly

Technical Requirements:

1. The flexible shaft shall be implemented according to JB/T8407-96.

2. The empty tension of the assembly is <10N, and the bearing tension is ≥3000N.

3. The operating temperature of the assembly is -40°C~100°C.

4. When the bending radius of the flexible shaft is greater than or equal to 300, the manipulation should still be free and unimpeded, and there should be a clear sense of position.

5. The stroke of variable speed flexible shaft is 39, and the stroke of high and low speed flexible shaft is 32.

6. The handle is black, the handle bar is chrome-plated, the rest of the exposed galvanized parts are blue-white zinc, and the surface of the controller is sprayed with plastic (camel gray).

7. The built-in micro switch should be automatically turned on when the small handle lever is in the neutral position.

8. "0106020101" is marked on the outer packaging and material card

9. Except for the mold itself, no other part of the assembly can bear the word "Wanjun".

10. The outer layer of the flexible shaft core is stainless steel, and the sealing material is polyurethane

11. The full length of the flexible shaft protection tube is covered with a spiral protective sleeve, and no color-plated parts are allowed.

Name:Gearshift Assembly

Technical Requirements:

1. The surface of the high and low gear control rod is sprayed with plastic.

2. The stroke of the flexible shaft is >50mm

3. Pull-off force between flexible shaft protection tube and joint > 3000N.

4. Pull-off force between mandrel and joint > 5000N.

5. The surface is sprayed with black paint to ensure the flexible and reliable rotation of the mechanism.

6. The welding part is guaranteed to be firmly welded without welding defects.

7. The length of the flexible shaft from end A to end B is 1200±5mm.

Name:Shift mechanism

Technical Requirements:

1. After the flexible shaft and the controller are assembled, the operation is light and flexible, and there is no sticking phenomenon;

2. Spread grease evenly on the rotating parts of the controller;

3. The controller can reset automatically;

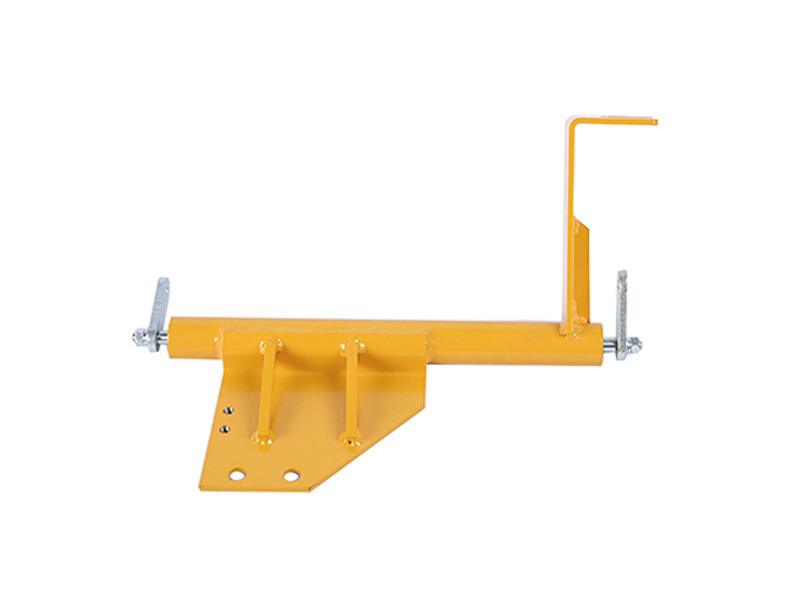

Name:Variator Linkage

Technical Requirements:

1. The rotating mechanism is sprayed with primer and yellow topcoat, and the connecting rod is galvanized.

2. The welding is firm to ensure the flexibility and reliability of the rotating mechanism after assembly.

3. The sharp angle in the bracket is blunt.

4. Other dimensions are determined by the manufacturer.

Name:Operator

Technical Requirements:

1. Clean surface.

2. Flexible operation without stagnation.

3. The gear selection stroke is not less than 60mm, and the shift stroke is not less than 70mm.

Name:Gearshift Assembly

Technical Requirements:

1. The appearance of the control assembly is clean and bright, free from damage, flexible in push and pull, and free of stagnation.

2. The gear position is required to be accurate, and there is no out-of-gear phenomenon.

3. Under the action of 3000N tension, the core wire and tie rod are not allowed to fall off.

4. The minimum bending radius of the flexible shaft is 250, and the working stroke is not less than 37mm.

5. The core must be cleaned before it is installed in the hose, and the entire length is coated with calcium-based grease.

6. The length from end A to end B is 1947±5

Name:Gearshift Assembly

Technical Requirements:

1. The appearance of the control assembly is clean and bright, without damage, flexible in pushing and pulling, and free of stagnation.

2. The gear position is required to be accurate, and there is no out-of-gear phenomenon.

3. Under the action of 3000N tension, the core wire and tie rod are not allowed to fall off.

4. The minimum bending radius of the flexible shaft is 250, and the working stroke is 36.

5. The core must be cleaned before it is installed in the hose, and the entire length is coated with calcium-based grease.

6. The length from end A to end B is 980±5

Name:Gearshift Assembly

Technical Requirements:

1. The flexible shaft shall be implemented according to JB/T8407-96.

2. The empty tensile force is not more than 20N, and the tensile force is greater than 3000N.

3. When the bending radius of the flexible shaft is greater than or equal to 300, the manipulation should still be free and unimpeded, and there should be a clear sense of position.

4. Both the controller and the flexible shaft should be filled with grease, the positioning bolts are brought to the oil hole, and the handle is bakelite.

5. The stroke between each gear of the control valve is 12.

6. The joystick has four gears, and the stroke H=39.

7. When the handle lever is in the neutral position, the external micro switch should be automatically connected.

8. On the original protective tube (keep the original protective tube), add ∅ 14 black spiral winding tubes, the length of which is basically the same as that of the hose part.

Name:Gearshift Assembly

Technical Requirements:

1. The surface of the manipulator is sprayed with black topcoat, and the appearance is clean and bright without damage.

2. The surface of the shift lever is chrome-plated.

3. Operating flexible shaft stroke≥18

4. The pull-off force between the flexible shaft protection tube and the joint is >3000N.

5. Pull-off force between mandrel and joint > 3000N.

6. The lengths of the two flexible shafts from end A to end B are 1410±5mm for flexible shaft 1 and 1360±5mm for flexible shaft 2

7. There should be an obvious manipulation mark on the joystick, and the position of the mark is accurate.

Name:Gearshift Assembly

Technical Requirements:

1. The appearance of the control assembly is clean and bright, without damage, flexible in pushing and pulling, and free of stagnation.

2. The gear position is required to be accurate, and there is no out-of-gear phenomenon.

3. Under the action of 3000N tension, the core wire and tie rod are not allowed to fall off.

4. The minimum bending radius of the flexible shaft is 250, and the working stroke is 36.

5. The core must be cleaned before it is installed in the hose, and the entire length is coated with calcium-based grease.

6. The length from end A to end B is 1910±5

7. The gear identification plate is separated from the assembly, packaged separately, and the identification is cut in the middle.

Contact Us

Sales: +86-15200188018

Fax: +86-13383198807

E-mail: chuanheng@hbqhgcjx.cn

Address: Wangguanzhuang Industrial Development Zone, Qinghe County

Our Products

The company has more than 100 sets of mechanical processing equipment and other equipment. CNC pipe bender, CNC drilling machine, welding machine, etc., with 4 advanced straight wire pipe production lines and 1 spray line

Follow Us

Scan to add wechat

Website